PROFESSIONAL RUBBER WASHERS AND RUBBER GASKETS MANUFACTURER

We are rubber silicone washers manufacturer. With more than 20 years’ experience, producing over 18,000+ kinds of rubber gaskets for our customers. Custom products available! For any special shaped products, fastest 48 hours can be achieved from design prototype to production samples.

Our Products

REQUEST A QUOTE

Need any quotation?

Cannot found your size?

Customized service needed?

ETOL can recommend the most suitable products for you according to your requirements. We ensure the consistent quality, best price, and on-time delivery. Contact us for more information!

What Is A Rubber Washer and Rubber Gasket?

Rubber washers and gaskets may seem small and insignificant, but within our vehicles, household plumbing, furnishings, and tools, the rubber washer serves as an indispensable element of composition. This particular type of gasket is a ring made from rubber, designed to be placed between two meeting parts. A washer of this sort can create a seal, or absorb impact and vibration. It might be used simply to help keep a fastening more secure. Flat rubber washers are made in a huge variety of different shapes and sizes – depending on their required application. They are also produced in a range of different types of rubber. Each offers different properties best matched to the task at hand. For example, some rubber gaskets need to withstand moisture. EPDM washers must withstand UV light, high temperatures, or certain chemicals and gases. In certain cases, the rubber may need to be more flexible, or rigid, or able to handle a variety of strains and pressures. We are a professional manufacturer of rubber gaskets; science and design have allowed us the capacity to create rubber with a huge diversity of properties.

Gaskets, Grommets, Seals, and Washers

The term rubber washer is often used as a blanket term to describe several different functions. For example a rubber gasket is used to seal two parts that will contain gas or liquid. Examples might include two connected pieces of tubing, or the closed body of an engine. While this particular role qualifies the term gasket, the term rubber washer is also commonly applied. Similarly, a grommet is used to protect material such as cabling, where it passes through metal or plastic. Although not technically acting as a washer, some may confuse the two – however you don’t need to feel confused as well!

Discovering a Diversity of Applications

Rubber itself is a material that humanity has been using for thousands of years. Natural forms of rubber can be harvested from a variety of plants. The first archaeological examples of its use date back to the Olmec culture of Mesoamerica, within this ancient society, the sap of the Heave tree – or rubber tree as it is most commonly known – was harvested. Over centuries, a range of methods were created to change the properties of rubber, such as vulcanization, curing, and creating compounds with other materials. Today, we also create synthetic rubbers – in fact more than half of the rubber we use is manmade, according to the International Rubber Study Group. The invention of synthetic rubbers has allowed even greater possibility in creating the perfect rubber for any application. This means that today’s rubber gaskets truly are at the height of their game!

Rubber washers offer flexibility and pliability, because rubber provides elastic properties. This means that this type of washer can conform to different surfaces, and respond adaptively to movement. All of this potential is why the humble rubber gasket can be found in so many different industries. Today’s achievements in the aerospace and automotive industries would not have been possible without the multi-talented rubber washer. Similarly, construction relies upon those small – and sometimes large – rubber rings for an array of tasks, including plumbing and electrical installations. In fact, original equipment manufacturing, and the creation of all of our household appliances, both draw heavily on the rubber gasket industry.

Selecting the Right Usage Method

Different types of rubber gaskets are best suited to different needs, so making an informed assessment can be invaluable. Each rubber washer is destined to be used between two conjoining parts, under compression. For example, a threaded bolt can be used to hold two objects together, when fastened with a bolt. To make the connection more secure, a rubber gasket can be added to the mix behind the bolt. Depending on whether a rubber washer is being used to create a water-tight seal, or for some other type of protection, washers may be placed behind the nut, behind the bolt, in between the two surfaces, or any combination of the above. The great thing about rubber is that it can be harnessed in so many different ways!

All the Right Properties

When choosing the right rubber washer for the job, it is important to consider what properties are required, and how much force and compression the washer will be subjected to. If the wrong type of rubber is chosen, the material can become over-stressed, and stop performing its function. In the production of such gasket, manufacturers consider a number of factors. Rubber is graded for tear resistance in kilo-newton. The capacity to resist abrasion is important for rubber washers that will be subjected to a lot of friction. The density and hardness of the rubber can also be hugely important. Density, within the world of rubber, is talked about in terms of specific gravity.

We will also consider tensile strength, which is how resistant the rubber is to being torn. Tensile modulus, in contrast, defines how resistant the rubber is to overstretching. On the other side of the same coin, certain applications may make elongation, rebound, and a high compression set desirable. These terms describe how stretchy and compressible the rubber is before it breaks, or its original shape will not return. Rebound resilience of sealing gasket is particularly important when a stationary part meets a moving part, such as within a modern window frame.

How Long Do Rubber Gaskets Last?

If you keep rubber gaskets for long periods, it is essential to know that rubber doesn’t last forever. Please take note that shelf life and storage time can affect the performance of rubber washers.

Things such as temperature, exposure to the sun, and humidity can impact the time you can store rubber washers. For instance, you can store natural rubber a maximum of 3 years, Neoprene 5 years, and silicone up to 20 years.

If you want to extend your rubber gaskets life, it is an excellent idea to choose a cool location, away from direct sunlight, and keep them in sealed, moisture-proof bags.

When to Replace Rubber Gaskets?

One of the main characteristics of rubber gaskets is that they can be used for a long time before wearing out. Replace them if:

- There is mold around the rubber washer at any time

- The rubber gasket is not sealing as it uses to because it is becoming thin

- There are visible fissures or cracks

- The rubber gasket can’t seal

- If you receive rubber gaskets from someone else and don’t know how much time they have been used.

If your rubber washers gets mold, you can easily clean it using one part of bleach, four parts of water and a brush. With the brush, carefully remove mold. If you want to maintain your rubber gasket clean and sanitize, you can clean it with lemon or vinegar.

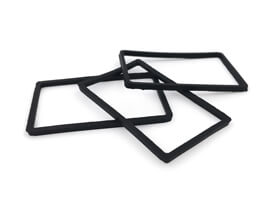

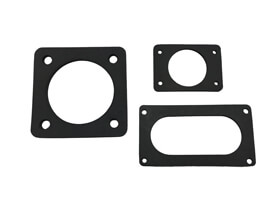

Which Shape Type Is Required?

At first glance, we might assume that rubber gaskets are generic, but their shapes and sizes vary – and picking the right one will make all the difference in terms of performance. Thick rubber washer and thin rubber washer are used in different environments. Selecting a flat and round rubber washer begins with measuring both the outside and inside diameters of the join that must be made. Some such gaskets may be a wide rubber ring, with a thin point of contact, while others may appear more as a rubber disk with a small central hole.

However, it’s undeniable that rubber washers can be made in any shape – ranging from rectangular gasket, to round gasket, to hemispherical gasket, and in fact any shape that may be required. For example, a curved washer with a tube recess is referred to as a saddle washer. And, while – thanks to their incredibly broad application – many rubber washers are sold in off-the-shelf sizes, please contact us for a rubber washer size chart. We also make custom washers to unique specifications.

Which Shape Type Is Required?

To change the properties of rubber gasket, it helps to understand the physics behind it. Rubber can boast its unique qualities thanks to long chains of molecules from which it is comprised. Introducing other substances that will create cross-links with these molecules – forming compound rubbers, can be transformative. Substances added might include plasticizers that act to soften. They might include vulcanite that reduces plasticity, and accelerators to speed that transformation alone. Antioxidants can be added to increase resistance to light, heat, or even soap. Some might simply add a splash of color to your rubber washers!

Some types of rubber used in washers are so common that they’ll probably sound familiar. For example, silicone washers offer impressive temperature resistance, safe for use within 150° and 500° Fahrenheit. Silicone is also tough in the face of ozone, UV light, and certain chemicals, but is not so battle ready when it comes to taking on petroleum based oils. Another familiar friend in the world of rubber is of course neoprene. Far from being used only in your holiday wet suit, neoprene is harnessed to create rubber washers that can withstand petroleum based oils, solvents, and even some acids.

Less familiar sounding rubber compounds used to create washers include Ethylene Propylene Diene Monomer, Nitrile, and sci-fi sounding Viton®. The right rubber type will not only ensure the right strengths and resistances, but also appropriate safety. For example, in the case of washers that will have contact with potable water or food.

What Manufacturing Process Creates The Washer You Need?

The process of creating the perfect rubber washer for any given application can also vary substantially. Some large rubber washers are die cut, which means that they are cut from a pigmented rubber sheet. Other small rubber washers are created by slicing rubber that has been molded or extruded into a long tubular mold. Types of molding include injection molding, and compression molding. In both cases, the rubber is heated to a liquid state and injected into the mold. However, in the latter case, compression is applied to ensure a more uniform finish.

A rubber gasket of a more complex shape may be machined or molded individually. Tools harnessed in the creation of that optimal rubber gasket may include extruders, lathes, presses, autoclaves and even water jet cutters. These techniques allow washers to be created that feature curves, ridges, asymmetry, and any other feature envisioned.

We provide professional customized service of rubber gasket, no matter what shape and material. If you have any needs, please contact us.

Why Choose Us

Plentiful Experience

With over 20 years’ experience on rubber and silicone industrial, we manufacturing products for over 5000+ customers in 60+ countries. ETOL aims to solve any difficult and special problems according to your requirements.

High Quality Products

Certificated by ISO9001, FDA, RoHS etc. All the products are compliance with RoSH standard. Over 5,000 customers from 60+ countries have a long-term cooperation with us.

Fast Delivery

Once you place an order, we will send it out as soon as possible. 3 Days fastest you will receive the products.

Great Variety of Products

Over 18,000+ kinds of products available, No need any mold cost, you can found the one you need directly!

Free Samples

Worry about the size and quality? Contact us to get free samples! You only need to pay the shipment, and we will send it to you for testing.

Custom service

From design, prototyping, mold making, mass production and delivery, we offer the one-stop complete process for you.

REQUEST A QUOTE

Need any quotation?

Cannot found your size?

Customized service needed?

ETOL can recommend the most suitable products for you according to your requirements. We ensure the consistent quality, best price, and on-time delivery. Contact us for more information!