PROFESSIONAL RUBBER STOPPERS AND RUBBER PLUGS MANUFACTURER

We are a rubber silicone stoppers manufacturer. With more than 20 years’ experience, producing over 18,000+ kinds of rubber products for our customers. Custom products available! For any special shaped plugs, fastest 48 hours can be achieved from design prototype to production samples.

Our Products

REQUEST A QUOTE

Need any quotation?

Cannot found your size?

Customized service needed?

ETOL can recommend the most suitable products for you according to your requirements. We ensure the consistent quality, best price, and on-time delivery. Contact us for more information!

Order Process Of Rubber Stoppers

- Step1. Please email us or submit a form to tell us about Plugs Sizes and any special requirements you need. Such as oil-resistance, high temperature resistance, UV resistance, etc.

- Step2. We will provide samples of rubber plugs for you to test according to your requirements.

- Step3. After the sample is confirmed, we will mass produce according to the quality standard of the sample, which takes about 5-10 days.

- Step4. Send the goods to your address via DHL, UPS and FedEx or by sea.

We have more than 3,000 kinds of rubber hole plugs to meet your needs. Please check our rubber stopper sizes. If you cannot found the suitable one, we can provide you with customized services of color, material and size. Contact us for details!

What is a Rubber Stopper, Plug, Cork, and Cap

Rubber stopper is a small accessory used in various holes for sealing, isolation and protection. It has a variety of applications, for example, silicone plugs are commonly used in medical and cosmetic industries as silicone is environmentally friendly and non-toxic, suitable for human contact. Due to its excellent physical properties, rubber plugs are more used in automobiles, machinery, electronics industries. Rubber plugs to fill holes could protect anything in the holes and work as a sealing parts.

Rubber parts have become an essential part of our everyday lives. Every appliance we use contains some sort of a part, like a rubber stopper, a rubber plug, a rubber cork, or even rubber caps. All of these, have different functions that can protect the machine or piece of furniture.

A rubber stopper is a small part that is most commonly used in laboratories. A part like this is placed to seal the opening of test flasks, tubes, and other types of glassware. The rubber stopper provides a tighter sealing. This way, they can ensure that the liquid or gas will remain on the container, no matter how the tube is placed or how hard the mixing process is. The laboratory rubber stopper is also caller as rubber bung plug.

The advantages of a rubber stopper are the following:

- It is long-lasting,

- It provides better sealing compared to other material,

- It is resistant to extreme temperatures,

- Its material is soft and can be shaped to fit any kind of opening,

- Prevents the contamination of the sample in the test tube.

A rubber cork works in the same way as the rubber stopper, mentioned above. However, its usage extends to a wide range of industries, such as electrical appliances, gas, automotive, industrial equipment, transport, railway, and construction. The advantages of rubber cork are many that make the rubber cork the perfect product for sealing applications. Namely:

- This material is extremely flexible and compressible,

- It can withstand extreme temperatures,

- It’s resistant to wear and tear, thus making it indestructible,

- It’s lightweight.

A small rubber stopper is a small part manufactured from natural or synthetic material. Just like rubber stoppers and corks, they are widely used to seal containers. Moreover, a rubber plug is also used to fill holes and keep liquid or gas from entering. For this reason, parts like these have found applications in the gas, chemical, shipping, and construction industries. Indicatively, its many advantages include:

- The rubber plug is weather resistant and unaffected by the UV and ozone negative effects,

- It is heat resistant,

- It is ergonomic as it doesn’t need screwing,

- It’s quick and easy to install,

- It’s long-lasting and resistant to cracking and tearing, thus keeping its tight fit for longer.

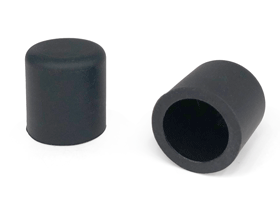

A rubber end cap, in reality, is a rubber body plug specifically designed to be inserted at the end of a pipe. Rubber endcaps can stop the insertions of dirt, dust, moisture, liquids, and other contaminants, and so, finds many uses in storage, manufacturing, transportation, and assembly. The main difference between a plug and rubber caps is that the first threads inside the part or pipe, while the cap threads on the external of it.

What are their most Common Applications

As you may have already realized, a rubber stopper, a rubber cork, a rubber plug, and rubber caps, are very similar. For this reason, most of them are used interchangeably. Nowadays, these parts have found commercial, industrial, chemical, and scientific appliances. Below, we will see in more detail how they are used in each industry.

Commercial Applications

A rubber stopper finds many uses in our everyday lives. For example, it can be used as a bumper to prevent damages and scratches. Moreover, many rubber caps as used like rubber feet in chairs and other furniture. This happens because rubber caps are resistant to friction and they are ideal to keep both the floor and the pieces of furniture intact. In addition to these, another common application of rubber stoppers is that of door stoppers. The soft material won’t leave a mark on the wall, no matter how many times or how hard a door hits it. Lastly, rubber plugs are used daily to cover holes and prevent spillage and flooding. Professionals, like plumbers, make excessive use of parts like these.

Industrial Applications

In recent years, a rubber stopper has taken up a key role in manufacturing. The vast majority of factories need to cover up containers to keep the temperature and moisture levels steady. Moreover, these containers usually hold heavy chemicals that need to be securely stored. A rubber cork can withstand a big range of temperatures and chemical substances, as it can resist tearing. For this reason, the main industrial application of a rubber plug is for the sealing of these containers.

Chemical Applications

Some of the chemicals that are widely used in manufacturing are hazardous and can potentially cause grave bodily harm. Therefore, the containers holding these chemicals must be secure and tightly sealed, both for storing and handling them. For example, some industries use acid, a chemical that is very dangerous for humans. Nevertheless, these parts are enhanced with materials that leave them unaffected by the chemicals. Furthermore, other substances used in manufacturing can be easily spoiled if they come in contact with the air. In this instance, a rubber plug becomes the shield that protects the chemicals from reacting with the environment.

Scientific Applications

One of the most common applications of rubber stopper is the scientific ones. A rubber cork is widely used as a seal for test tubes, flasks, and other laboratory glassware. While chemicals can be stored in jars with screw-on caps, chemists and scientists use them in flasks that don’t possess any kind of cap. For this reason, in the pharmaceutical industry, scientists use tube stoppers to secure the tubes while mixing the chemicals. These parts also prevent contaminants from entering the container so that the results are pure. For the scientific applications, the rubber stopper with hole usually has one or two holes from which the scientist can insert a thermometer or other tools to examine the liquid inside.

What is their Usage Method

The various rubber parts come in handy in many cases. For this reason, it is important to know how to apply them when you need to. Below, you will find a step by step explanation on how you can place a rubber stopper in a container.

Step 1: First of all, you need to get a rubber plug that is the right size for your container. Every rubber cork is wider at its one end so that you can pull it out easily. So, when you purchase a rubber stopper, you should pick one with one end wider than the opening and one end narrower than it. This rubber plug will fit perfectly.

Step 2: Determine if you need a solid rubber plug or rubber hole plug. This depends on the chemical you would like to use and how reactive it is.

Step 3: Use a small amount of lubricant on your container so that the rubber stopper slips in easily. This way, you will prevent damage to your test tube by the force that will be applied. When you apply the lubricant, make sure that you don’t spill any of it within the tube.

Step 4: Shape the rubber stopper with your fingers and then insert it to the container. Apply enough pressure to puss it until you feel the resistance is too much. In this step, you need to be very careful as excessive pressure might break or crack the container.

Rubber stoppers, plugs, and corks are all inserted in the flask and so you can apply them the same way. However, rubber caps are quite different as they are placed in the external of the container. Here is how you can apply these parts:

Step 1: Make sure that the external part of your container is clean from chemicals or dust.

Step 2: Apply a small amount of lubricant around the edges so that the cap slides easily. In this case, you don’t have to be as careful with the lubricant as in the case of the rubber plug.

Step 3: Press the cap until it fits perfectly.

Different Shapes and Types of these Rubber Parts

A rubber stopper and a rubber cork are oftentimes cylindrical with one tapered end. These parts have three distinct types:

- The solid stopper: this rubber stopper is the most common one as it finds many applications in our everyday lives. Moreover, this rubber plug is also used in wineries and breweries.

- The one-hole stopper: this type of rubber part is very common in laboratories. The hole allows the scientists to insert thermometers and other devices in the container, without having to open it. This kind of rubber cork is manufactured in all of the sizes.

- The two-hole stopper: this is a rubber cork used in the laboratories. It enables scientists to insert multiple instruments in the container at the same time. Even though it possesses two holes, it is one with the tightest fit.

- Tapered caps and plugs: the most common shape for a rubber plug is the tapered one. It provides a tight fit and for this, it is great for everyday use. You can find it in many diameters.

- Push-fit caps: these rubber caps are ideal for storage and transportation as they provide a tight fit without the need for fasteners. They come out in various shapes and sizes.

- Rubber bolt caps and plugs: these screw end caps are often applied to hydraulic hose fittings.

- Vinyl end caps: vinyl caps are very flexible and stretchy. They provide a very tight fit and they are also very easy to remove.

- Protection for pipes caps: These round rubber end caps for pipe protect pipes from damage, spillage, and contamination. Rubber end caps for round tubing are the most common shape. They are specialist pipe endcap and you can find them in various diameters.

- Parallel protection plugs: This type of rubber plug protects the pipe or container from dirt, moisture, and corrosion.

Material Classification Used for their Manufacturing

The most common material used for the manufacturing of these parts are the following:

- Natural rubber: This all-natural material is known for its resistance to abrasion. Moreover, it possesses excellent flexibility in lower temperatures, from -40°C to 68°C. However, it is not recommended for use with oil, gasoline, and ozone sunlight.

- Silicone: This might be the most flexible material used for the manufacturing of a rubber stopper. Silicone is showing great resistance to extreme temperatures and compression.

- Styrene-Butadiene Rubber (SBR): SBR resists water and liquid pressure, and for this, it is ideal for rubber caps.

- EPDM: This rubber can be used under any condition as it has resistance to the weather conditions, the chemicals, and the heat.

- Neoprene: This material has excellent resistance against acids. Moreover, it can be used in any weather condition.

- Nitrile rubber(NBR): Rubber plugs used in automotive and machinery, usually made of this material

A rubber stopper is a part widely used today. You can pick the right rubber plug for your needs. You can contact us to get our rubber stopper sizes chart, and we can also customize various special-shaped stoppers for you. We have a mature production line, from design to finished product, it only takes 48 hours at the fastest. Please contact us for a quote!

Why Choose Us

Plentiful Experience

With over 20 years’ experience on rubber and silicone industrial, we manufacturing products for over 5000+ customers in 60+ countries. ETOL aims to solve any difficult and special problems according to your requirements.

High Quality Products

Certificated by ISO9001, FDA, RoHS etc. All the products are compliance with RoSH standard. Over 5,000 customers from 60+ countries have a long-term cooperation with us.

Fast Delivery

Once you place an order, we will send it out as soon as possible. 3 Days fastest you will receive the products.

Great Variety of Products

Over 18,000+ kinds of products available, No need any mold cost, you can found the one you need directly!

Free Samples

Worry about the size and quality? Contact us to get free samples! You only need to pay the shipment, and we will send it to you for testing.

Custom service

From design, prototyping, mold making, mass production and delivery, we offer the one-stop complete process for you.

REQUEST A QUOTE

Need any quotation?

Cannot found your size?

Customized service needed?

ETOL can recommend the most suitable products for you according to your requirements. We ensure the consistent quality, best price, and on-time delivery. Contact us for more information!