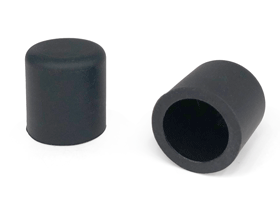

Rubber test plug

A rubber test plug is commonly used when different sewer and water systems have to be tested and/or repaired. In most cases, it is applied to the ends of PVC or metal pipes and a rubber test plug is meant to test the pressure in stack vents, dry waste, as well as other vent pipes that are a part of the system. In order to meet various building regulations and laws, most states will require the use of a rubber test plug, especially if the construction is residential. It comes in various shapes, sizes, and models, and it’s extremely important to choose a rubber test plug that is suitable for the size of the pipe opening, otherwise, it cannot be used properly.

Since it is manufactured from high-quality rubber, it is long-lasting, meaning that it will provide a long service life. Besides this, a rubber test plug has other properties as well, including being resistant to corrosion, dust, grime, dirt, high and low temperatures, as well as liquids, chemicals, and humidity. These properties are exactly what allows different industries and manufacturing plants to use a rubber test plug for a wide range of processes and applications. Another interesting thing is that they can be entirely customized, meaning that customers can choose every single characteristic of the rubber test plug, including the color.

In order for it to function properly, the rubber test plug must be appropriate for the seal pipe section. Also, any grease, debris, or dirt must be removed before the plug is installed, since if it isn’t it won’t be able to test the pressure properly. Additionally, there must be no grease or dirt between the seal and the plug, especially since it might hinder the rubber test plug from being installed. This means that customers need to be extra careful about how they install a rubber test plug.

Our Products

- Material: EPDM/NR/SBR/Silicone/FKM/NBR/CR

- Hardness: 30-90 Shore A

- Temperature Rang: -70℃ to 220℃, we can customize products with a temperature resistance of more than 300℃.

- Colors: Black,White Or according to the Pantone NO#.

- Custom service available, we can offer special plugs according to your requirements.

Do you need a quote? Or need to place an order?

We also provide customized services, and can make various non-standard silicone rubber parts according to your drawings or samples.

Welcome to contact us for more information!