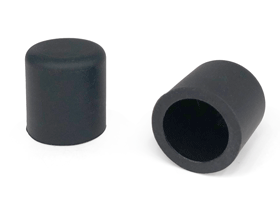

Rubber test plugs

In many parts of the world, construction regulations make it mandatory to test the piping systems of the construction you are building at a low pressure of water. This testing ensures that water pressures don’t overcome the installed pipes later on when the building is finished. There are various methods and options for checking this water pressure, but the most validated and inexpensive one is the rubber test plug.

A rubber test plug is a plug made to fit inside a pipeline on the lower ends of a pipe system where it faces a tremendous water flow head-first. The rubber test plug is left like this for a few hours to ensure the water force covers all areas of a pipeline. Meanwhile, the integrity of the rubber test plug is examined to check if it holds to ample water supplies or not. If the channel starts leaking at places, the pipeline is considered to generate excess water pressure and is then modified.

By this, it is easy to guess that rubber test plugs are actually quite crucial for testing. You must understand these are often confused with rubber test caps, even by plumbers themselves, but are actually quite different from them because while rubber test caps are easily removable, rubber test plugs are fitted with a wing nut that ensures they fit tightly into the pipe.

Rubber test plugs can work with all kinds of pipes, from PVC, iron, steel, and even cast iron. Their design allows for effortless and straightforward installation. If you don’t use rubber test plugs for your construction, you won’t be able to conduct proper and professional low-pressure testing, which is mandatory for building. If regulations ask for it, which most of them do, you will also need to do a drain pressure test in which rubber test plugs are used again.

Our Products

- Material: EPDM/NR/SBR/Silicone/FKM/NBR/CR

- Hardness: 30-90 Shore A

- Temperature Rang: -70℃ to 220℃, we can customize products with a temperature resistance of more than 300℃.

- Colors: Black,White Or according to the Pantone NO#.

- Custom service available, we can offer special plugs according to your requirements.

Do you need a quote? Or need to place an order?

We also provide customized services, and can make various non-standard silicone rubber parts according to your drawings or samples.

Welcome to contact us for more information!