Industrial rubber is increasingly used today precisely because of its easy and simple production. Also, this type of rubber is available almost everywhere. But, there are some reasons why they are using so often. The material from it’s been made is much more resistant than natural rubber, both to abrasion and grease and oil. Due to its properties and formulation, this rubber is resistant to chemicals and hydrocarbons. Its use is ideal for an environment where there is corrosion. Incredibly withstands changes in both heat and weather. They are so resistant that not even a flame can do anything to them. Its flexibility, in addition to resistance, makes industrial rubber very popular.

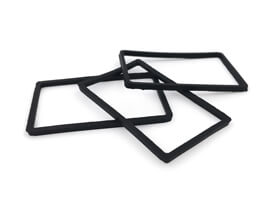

When we talk about industrial rubber, we can’t help but mention rubber gaskets. Thousands of machines, but also home and kitchen appliances simply would not be what they are without these gaskets. The range of their use is incredible: from the simple possibility of closing our refrigerator properly to the construction of bridges and other important buildings. Gasket made of industrial rubber is used primarily to prevent leakage of gas or some liquids. In addition to this use, it is also used as an obstacle, or better said separating two buildings, and can also protect certain external elements. As it fights moisture well, you can also find it in camera lenses just so that the lens does not have moisture stains and loses focus.

As, as we can see, the use is extremely wide, so a large number of gaskets of different sizes and shapes are produced. The same application can rarely solve two or more problems. That’s why you can find specific gaskets on the market for each use. So our recommendation is to search for them online. They can also be cut and shaped according to the customer’s wishes and needs.

Do you need a quote? Or need to place an order?

We also provide customized services, and can make various non-standard silicone rubber parts according to your drawings or samples.

Welcome to contact us for more information!