Adhesive backed rubber gasket is an advanced type of rubber gasket that is normally used in a variety of industries as well as in many other places. It is safe to say that many industries, such as the oil and gas industry, wastewater management and the auto industry would be very difficult to function without regular rubber gaskets, as well as adhesive backed rubber gasket. Also, plumbers inevitably have rubber gaskets in their equipment, because for all piping and plumbing jobs it is absolutely necessary to have adhesive backed rubber gasket. Numerous laboratories and chemical processing plants take advantage of chemically stable materials such as silicone from which an adhesive backed rubber gasket can be made.

Although the most common use of adhesive backed rubber gasket and rubber gaskets is generally to act as a seal, which you may have concluded because it is useful for piping, plumbing and so on, it is certainly not the only purpose of rubber gasket. The rubber gasket can also be used as a vibration damper, so it is placed between two machines or two parts of the machine that produce high vibrations. In addition, they can reduce noise, in the same way as they absorb vibrations. Instead of hearing two metals hit each other, the whole process will be totally quite. You will find rubber gaskets as supporting mounts as well.

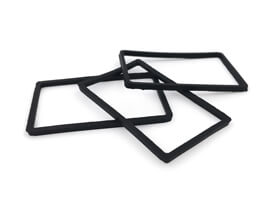

Compression molding and injection molding are the two most common forms of rubber molding that are also used to make adhesive backed rubber gasket. This allows you to create rubber gaskets of different sizes, whatever you need. Also, all rubber materials can be shaped in this way, so it is up to you to customize everything or to choose something premade. If you want different colors to make it easier to figure out which rubber gasket is where, emphasize it in the order.

Do you need a quote? Or need to place an order?

We also provide customized services, and can make various non-standard silicone rubber parts according to your drawings or samples.

Welcome to contact us for more information!