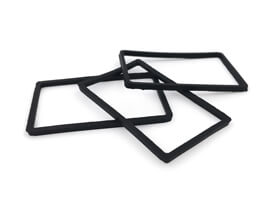

An extruded rubber gasket is a rubber gasket that has been pressed to create a special shape, which is why it is often called a custom extruded rubber gasket. This manufacturing method produces a product that offers a tighter seal since the material is tightly compressed and made in the precise shape and size which is needed. In other words, a custom extruded rubber gasket is a form of a custom sealing device for a variety of applications. The word “extruded” means that the rubber has been forced through a die having the desired cross-section shape. These dies can be simple shapes such as circles, squares, ovals, triangles, and custom shapes based on the application you need the gasket for.

A custom extruded rubber gasket is made of rubber which can be manufactured using many different materials, both natural and synthetic. Synthetic ones used to make the gasket are very resistant to oils, fuels, water and other liquids and chemicals. They are also very resilient to temperature changes and can withstand temperatures both very high and very low. Depending on the material used, we can expect a custom extruded rubber gasket to withstand temperatures as low as negative 70 degrees Celsius and as high as 270 degrees Celsius.

A product like a custom extruded rubber gasket is very versatile and offers a wide variety of benefits, including sealing and protection from various effects and contaminants. Due to their custom made shape, they could also be used to allow the passing of liquids and gasses. As for how far could you take the customization, there are virtually no limits. We will gladly collaborate with you on your project, and we will manufacture the exact gasket you need, provided that you supply us with the proper design of the product you need.

Do you need a quote? Or need to place an order?

We also provide customized services, and can make various non-standard silicone rubber parts according to your drawings or samples.

Welcome to contact us for more information!