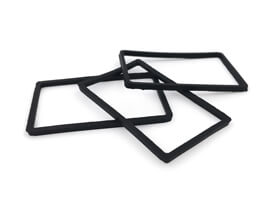

Though most people think that rubber gasket manufacturing is extremely complex and daunting, it isn’t. In fact, our company specializes in providing excellent rubber gaskets that have been utilized across all industries. Our rubber gasket manufacturing method includes a wide range of punching and cutting procedures. The most common process involved is punching, which will require a specifically bent metal strip that features a knife at the bottom. Next, a power press will push the substance into the blade, which then produces the holes needed. Besides this traditional technique, our rubber gasket manufacturing processes also utilize water jet cutting, which will allow quick and precise production.

Our rubber gasket manufacturing plant also utilizes laser cutting, which is quite similar to the aforementioned technique. Now, as the name implies, we don’t use a water jet for producing the holes, instead, we utilize a precise laser. By doing this, we offer high-quality, precise end products to our clients. Both of these options are incredibly fast, meaning that our company can produce thousands of rubber gaskets, hence, we can ensure that our customers get their goods in a timely manner. Yet another rubber gasket manufacturing process that could be implemented is strip cutting.

When we use this particular technique for your rubber gasket manufacturing, we utilize a rotary blade that forms long sheets of rubber into strips. It has to go over the initial material, and by utilizing several rotation knives, it creates the final strip. Lastly, extremely precise finishers trim, punch, and package our rubber gaskets to all the industry’s standards. Keep in mind, all of these processes are reliable and precise, so, no matter what our customers choose, they’ll receive high-quality rubber gaskets. It’s worth mentioning that we have an experienced and skilled customer support team, so, if our clients need to know more about our rubber gasket manufacturing processes, they can contact them.

Do you need a quote? Or need to place an order?

We also provide customized services, and can make various non-standard silicone rubber parts according to your drawings or samples.

Welcome to contact us for more information!